Fuerstar is a leading grain processing machinery manufacturer in China. Offer not only single flour mill machine, but also small flour mill plant (2TPD ~ 10TPD) and complete set of flour processing plant (20-40TPD) for processing wheat, corn, cereals and so on. We have helped our customers to set up flour mill projects in many regions, like Ghana, Zambia, Argentina, Ethiopia, Uganda, etc.. Depending on the reliable quality, reasonable price and professional experiences, Fuerstaris definitely the Best choice!

▼Technical Specifications

| Parameter | Value |

Capacity | 50-100 ton per day |

Flour Fineness | 40-120 mesh (fineness can be adjusted) |

Yield Rate | (1) Maize flour 70-75% (30-40-50 mesh) (2) Feed powder 25-30% |

Power | About 280-320KW |

Voltage | 380V 3Phase 50HZ |

Dimension | 32*16*9m (L*W*H) |

Raw Material | Raw Corn/Maize |

Final Products | Corn Grits,Corn flour and Corn bran |

▼Types of 50-100TPD Maize Flour Milling Machine

Different investments, different footprints. We offer a variety of processing technologies and maize milling plant layouts to meet the unique requirements of our diverse clientele. Whether you need 50 or 100 tons per day, we have the right milling machine for you.

▼Overview of the Corn Milling Plant Process

Our experienced engineers craft solutions based on your unique requirements. Whether it's cleaning, grinding, or packaging equipment, we design bespoke solutions to ensure the perfect fit for your operation.

1)Cleaning Machine

The main cleaning machine: Vibrating Screen, Destoner and Magnetic Separator.

Vibrating Screen is mainly used in material cleaning production to screen out big, medium, small and light impurities. Used in material cleaning production to efficiently screen out impurities of varying sizes, it features a special sealing design to prevent dust, high-quality vibration motor, low noise, steady operation, large capacity, low energy consumption, and effective cleaning. Ideal for grains and works well with vertical suction separator.

Gravity De-stoner (different specific gravity): Remove the inorganic impurity (stones and mud)having similar size but different specific gravity by specific-gravity stoner.

Magnetic Separation(Different magnetism): Remove magnetic metals by magnetic selector.

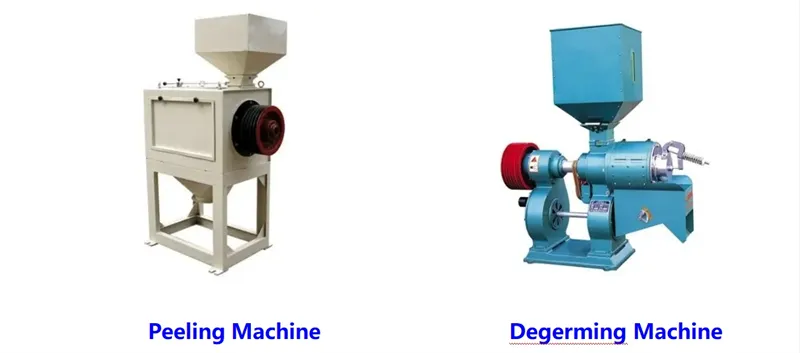

2)Peeling Machine

The working principle is to clean the wool corn through the feed port into the corn peeling polishing machine peeling chamber. By controlling the feeding speed of the feed port, the pressure of the pressure valve, so that the peeling chamber produces a certain pressure. Between the rotating drum and the sieve, the material is squeezed and rolled to peel, remove embryos, black umbilical and polished. Under the action of the wind, the kernel bran is separated to produce corn kernel (corn ballast).

3)Flour Mill

This flour milling machine is a single machine. Due to perfect design, high efficiency, electricity-saving, easy operation, low maintenance and low noise. It is ideal for small scale production of wheat flour, corn flour, sorghum flour, rice flour, soybean flour. It can process almost all kinds of grain materials. Because of compact construction, small size and low cost, this series of multi-function coarse grain flour milling machine is favored by farmers, home uses or small flour mill workshop to make small scale flour from various grain. It is also widely applied in small wheat / maize / rice milling plant.

Plansifter is one of the key equipment of flour milling process and grain grinding production. Plansifter is generally used for screening and grading after grinding. It can also be used as checking sifter.

4)Packing Machine

Quantitative flour bagging machine is a complete set of packing system for wheat and maize grinding and flour milling production, which includes both weighting and packing. It can be used for packing flour and other powder. It is featured of adjustable feeding speed and high feeding accuracy. This is a no hopper scale. The bag itself is a scale. It can overcome the buffer hopper problem, to ensure the measurement accuracy of the filling material.

▼Milled Corn production

Our commitment to delivering top-notch products is reflected in the excellent quality of the final corn flour produced. We prioritize the satisfaction of our clients by consistently providing superior milling solutions. Get a Free Quote Now

▼Why Choose Our Corn Milling Machine?

Decades of Expertise: Our team has expertise in design, automation and equipment manufacturing.

Cutting-edge Innovation: Our flour milling machines and automated grain processing equipment deliver high precision, low loss and safe, quality output.

Resource Advantage: Leverage our decades-long experience for world-class solutions in flour processing and grain management.

Market: Our corn milling machines cater to a diverse market, including: Local millers and entrepreneurs, Agricultural cooperatives, Food processing businesses and more.

For inquiries, quotes, or additional information, please contact us. FUERSTAR is dedicated to delivering high-quality corn/maize flour processing solutions tailored to your needs.