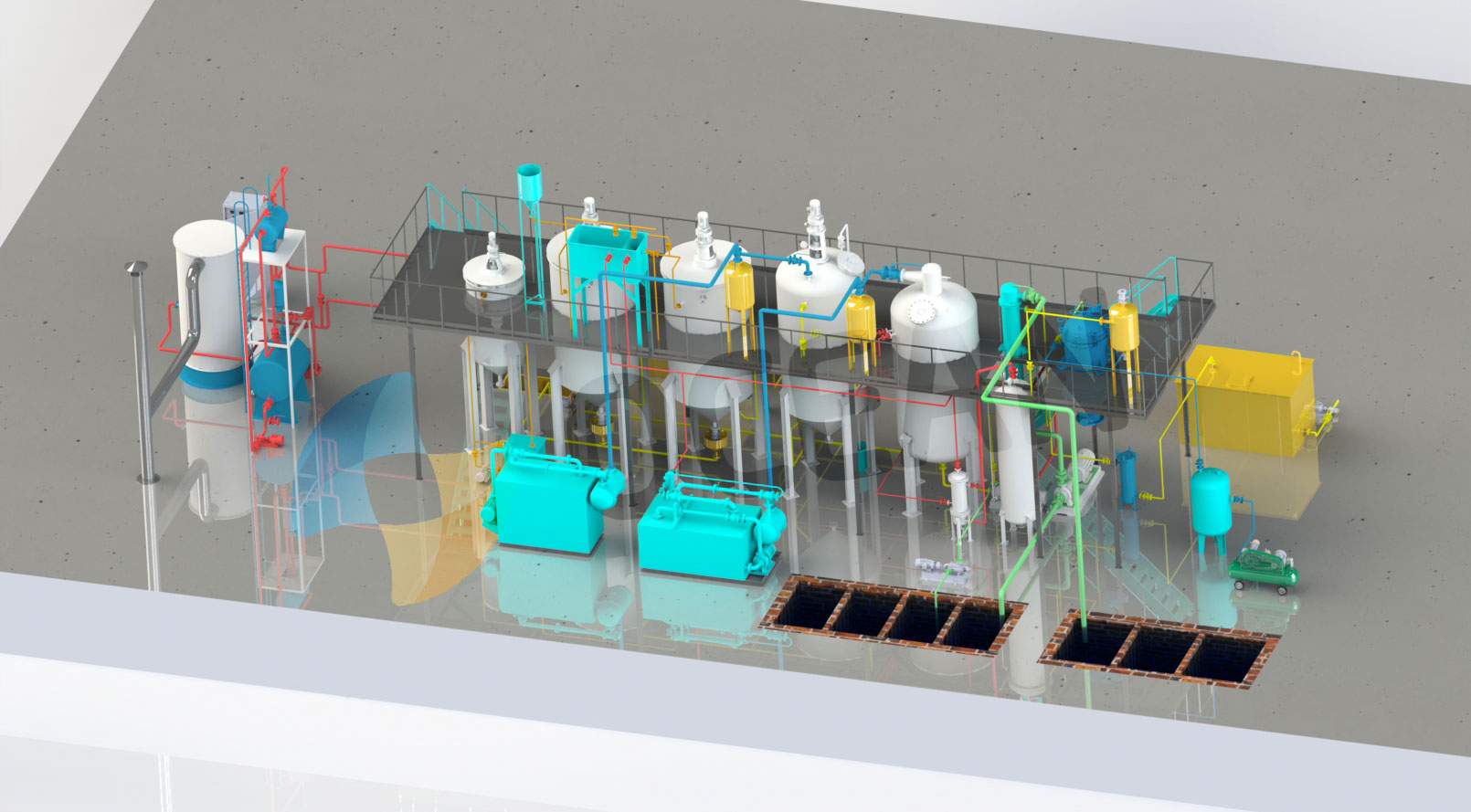

A Complete Edible Oil Refining Process

Crude oil→Water washing and alkali refining→ Dephosphorization degumming→Continuous decoloration→Continuous deodorization→To fractionation and dewaxing workshop

Degumming: To remove the gum impurities, and prepare for the subsequent refining processes.

Deacidfying: To remove the free fatty acid in the crude oil.

Decoloring: To remove the pigment in the crude oil by adding active bleaching earth, so that can improve the oil quality.

Deodorizing: To remove the odor in the oil, so that can improve the flavor, stability, color and quality of the oil.

Dewaxing: To remove the wax in the oil and improve the quality of the oil.

*Some oils like sunflower , corn germ , cottonseed and rice bran oils contain some percentage of wax which is to be removed througlhe process of dewaxing . Dewaxing is used after the refinery process.

What types of edible oil refineries can we produce?

1-30TPD intermittent edible oil refinery

10-50TPD semi-continuous edible oil refinery

30-1000TPD fully continuous edible oil refinery

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.